Tate & Lyle, a global leader in ingredient solutions receive a huge automation boost with an industry-first automated laboratory, which aims to deliver faster and more accurate ingredient design, accelerating go-to-market for new food products.

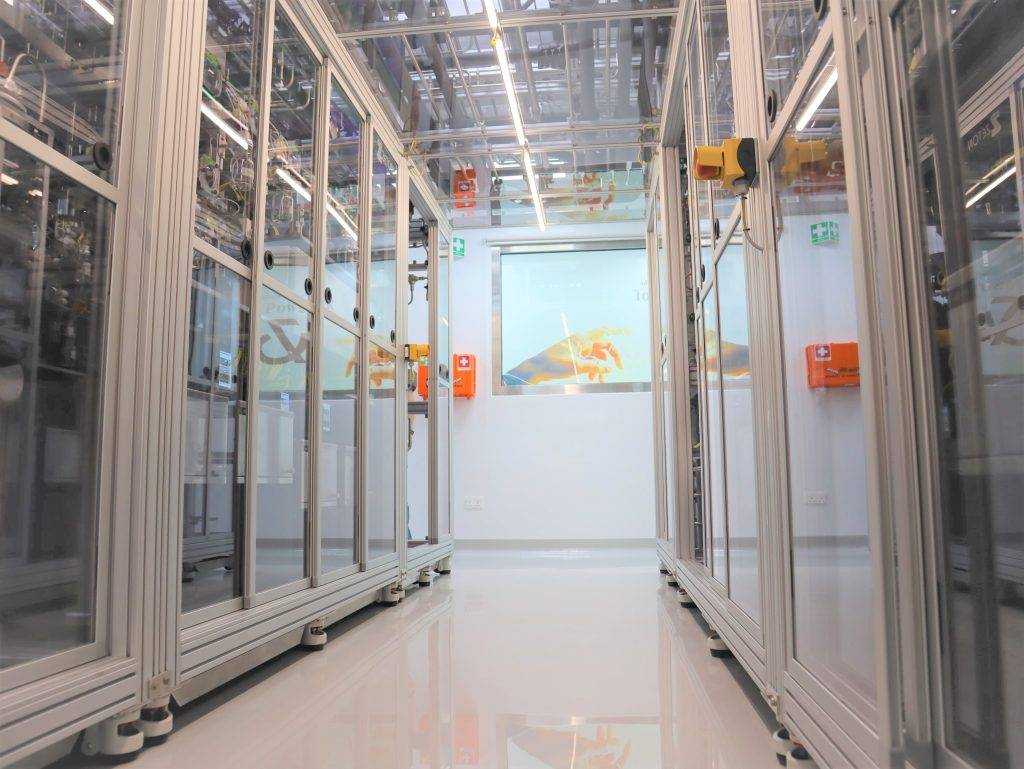

Members of the media were treated to a tour of Tate & Lyle’s automated lab aptly called the Automated Laboratory for Ingredient Experimentation, or AlFIE, that is located in Singapore, just one of its Customer Collaboration and Innovation Centers around the world.

A look at ALFIE, at Tate & Lyle’s Singapore site.

The lab overall consists of two systems, one designated for sample preparation, while the other focuses on characterization tests of the prepared samples. Replacing what would have been a ‘regiment’ of scientists on lab benches hunched over and manually executing these two processes, Tate & Lyle execs shared that data-driven robotic automation now actually increases productivity as much as ten times the current rate.

A sample preparation process

The accelerated sample production, characterization, and modelling more quickly yields results which are enhanced by machine learning capability that predicts and produces prototypes of solutions for customers.

On top of that ALFIE is connected to a Tate & Lyle site in Chicago, where another team of scientists can contribute to trialling new ingredients and creating new solutions.

Why ALFIE?

Customer problems statements, like needing to reduce sugar of chocolate bars or baked goods by 30% can be solved more quickly whilst maintaining the taste of the product.

It can be a challenge to maintain taste of the food item while improving its healtfulness, as customers prioritize taste above all else.

Nick Hampton

Chief Executive, Nick Hampton explained, “So we take sugar out, we take fat out, we put fiber back in, we put protein back in,.. we change the Structural Function of the food and that changes the mouthfeel and the texture (of the food) in the mouth; and the mouthfeel is the critical carrier of taste.”

Nick shared that ALFIE can potentially reduce the time required for ingredient innovation processes by starting with better prototype solutions, and cycling through the processes faster.

In this way, the next steps in the process, sensory and consumer testing alongside customers, can happen faster as well.

Victoria Spadaro Grant

Victoria Spadaro Grant, president of innovation and commercial development, also said, “Asia has the widest array of taste and mouthfeel experiences, so there is a very big window of possibilities for creation of experiences for Asia which could potentially cater for another part of the world.”

Singapore Economic Development Board (EDB) Senior Vice President of Global Enterprises, Marcus Dass, had stated that the opening of the new automated lab reflects Singapore’s position as a trusted hub for the region and for cutting edge innovation in the food and nutrition space. “We look forward to the lab accelerating ingredient solution discoveries and enriching Asia’s food innovation ecosystem.”

Seven years in the making

Nick shared how he had initiated the multi-million pound project, so that the organization would be better able to transform to a new product development process for its mouthfeel solutions and empower its scientists to accelerate experiment design, analysis, and delivery of solutions.

Another outcome from this also is the cost savings that are passed on to customers due to the lower cost and lesser time required to create solutions and ingredients.

Tate & Lyle is a 160 year old organization that partners with customers to provide consumers with healthier and tastier choices when they eat and drink. They are proud of their expertise in sweetening, fortification, and texture that enables them to develop ingredient solutions which reduce sugar, calories, fat, while adding fiber, protein, texture and stability, in food items in the beverage, dairy, bakery, snacks, soups, sauces, and dressings categories.