By Sri Nurhayati, Techmind.id

The manufacturing industry in Indonesia has faced increasingly complex challenges in recent years. With rising global competition and pressure from consumers for high-quality products at competitive prices, domestic manufacturing companies have had to adapt quickly. Amid this situation, the skills crisis has become a serious problem, where many companies struggle to find skilled and experienced workers. Additionally, fluctuations in raw material costs and regulatory changes have further burdened industry players.

Challenges in Indonesia’s Manufacturing Industry

In this context, process automation has emerged as a solution that is not only relevant but also urgent. In an increasingly advanced digital era, automation technology offers companies a way to improve operational efficiency and productivity without having to rely entirely on human labor. This automation also helps companies maintain high quality standards while meeting customer expectations.

Seamless integration with existing enterprise applications and systems eliminates the need for complex data extraction or manipulation, making the adoption of this technology easier.

Mr. Pingadi Limajaya, CIO of PT. Walden Global Services (WGS) emphasized that “the implementation of automation technologies such as RPA can provide companies with a significant competitive advantage. By automating repetitive processes, companies can shift their human resources’ focus to more strategic areas, such as innovation and product development. This is crucial, especially in today’s rapidly changing market.”

He also highlighted that “companies adopting automation not only experience improvements in operational efficiency but also in product quality. Automation allows for better quality control, which ultimately increases customer satisfaction. In Indonesia, with the existing challenges, companies that quickly adapt to automation technology will have a greater chance of surviving and thriving.”

Benefits of Automation in Business Processes

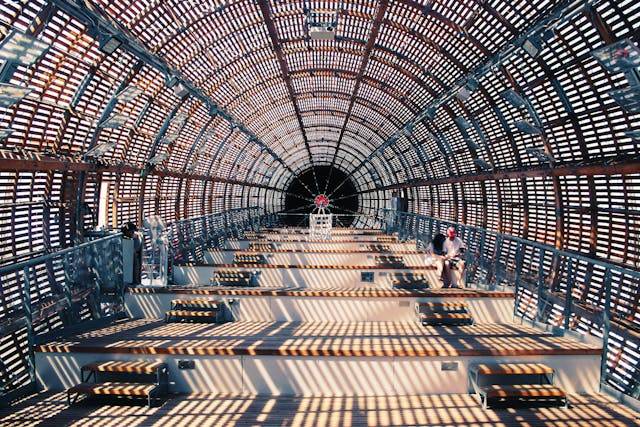

Automation in factories

Automation allows companies to accelerate critical processes such as equipment inspection and product quality control. By using mobile applications and automated workflow systems, companies can perform inspections more efficiently.

Real-time data and image collection provide the ability to respond to problems quickly, reducing downtime and improving overall productivity. In a highly competitive industry, excellence in quality control becomes key to success.

Moreover, automation also contributes to improvements in the procurement process. In Indonesia, where supply chains are often complex and vulnerable to disruptions, having an efficient procurement system is crucial. With automation, supplier selection and evaluation can be done more systematically, reducing waste and increasing the speed of raw material procurement.

Nintex and Walden Global Services

PT. Walden Global Services (WGS) now introduces Nintex solutions to the local market, making it easier for manufacturing companies to automate various critical business processes. Nintex offers a user-friendly interface, allowing users to build automation without needing in-depth programming knowledge. Seamless integration with existing enterprise applications and systems eliminates the need for complex data extraction or manipulation, making the adoption of this technology easier.

One of Nintex’s advantages is its ability to improve accuracy. By automating routine tasks, Nintex reduces the risk of human error, resulting in more accurate data and better process consistency. Additionally, this repetitive automation also increases employee productivity, freeing up their time to focus on more strategic work.

In conclusion, in facing complex challenges, process automation is not just an option but an urgent necessity for the manufacturing industry in Indonesia. By adopting solutions like Nintex delivered by WGS, companies can meet customer expectations and address the skills crisis more effectively.

This digital transformation becomes a strategic step towards sustainability and growth.